Today Uncle Walter guided me thru building the support piece for a balance beam I’d picked up from Calgary IKEA.

The balance beam is cleverly constructed in classic IKEA fashion. All but one piece break down to flat easily transported pieces. In order to get it back to Alaska I abandoned the support beam after hacking off one end to be a guide. I did so knowing that Uncle Walter would almost certainly be willing to lend his expertise to fashioning its replacement.

It transported home easily.

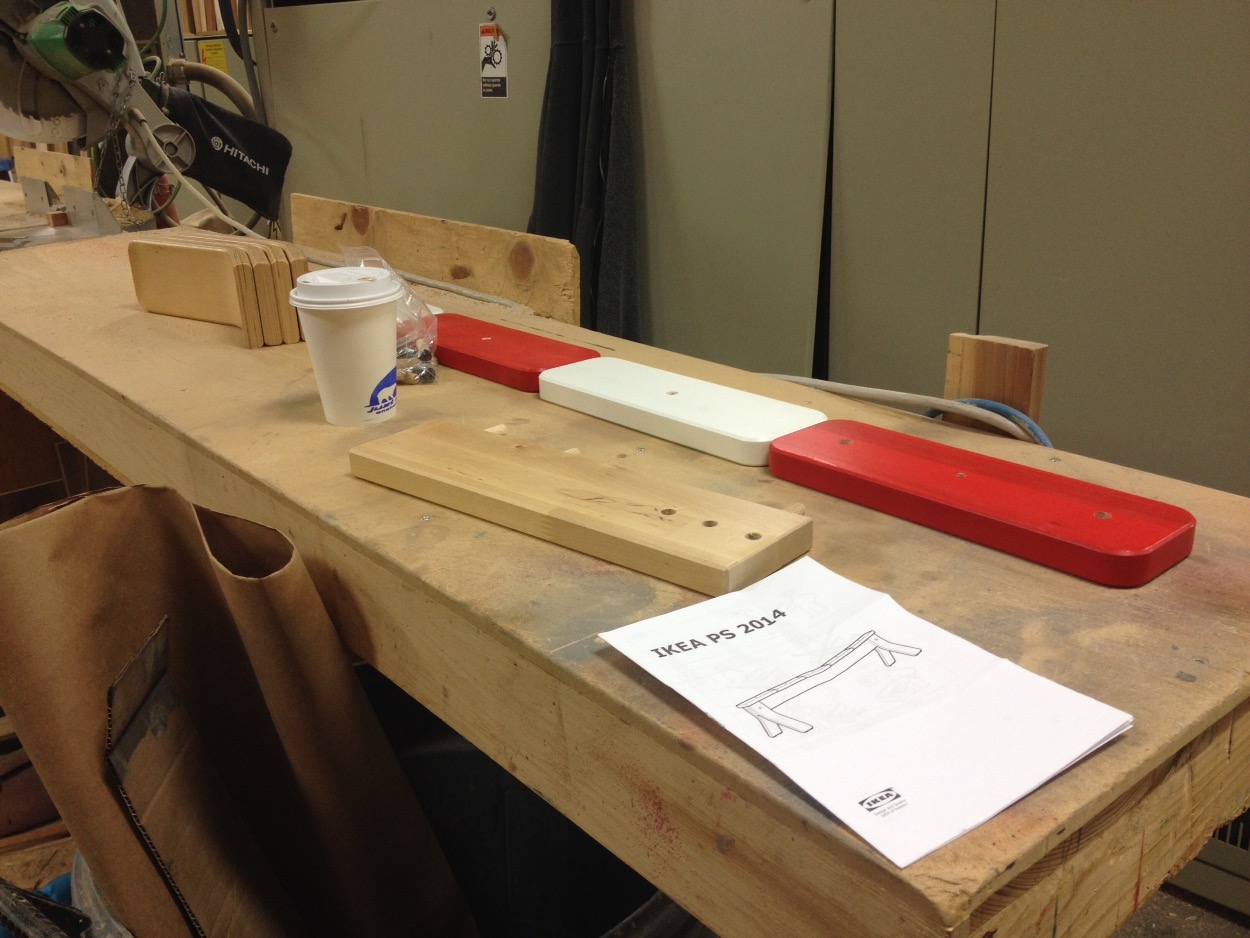

This morning I met UW at the shop. We laid out the pieces. I showed him the instructions for assembly, and the bit I’d brought back to use as a template.

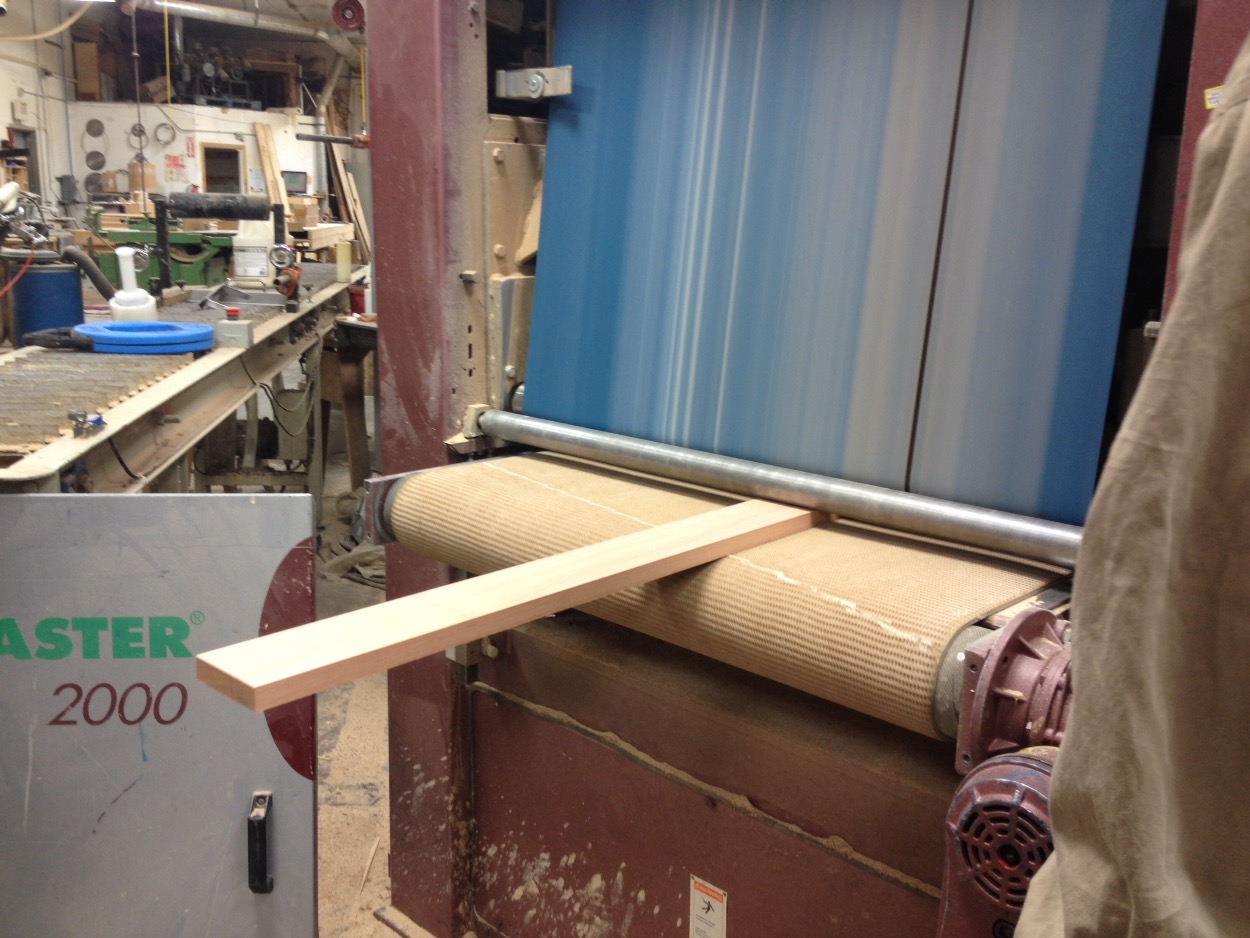

There was a nice piece of scrap lumber reminescent of mahogany that possessed the requisite qualities. UW ripped it to the correct width. Mark ran it thru a machine that squared everything up. Then several passes thru a sander.

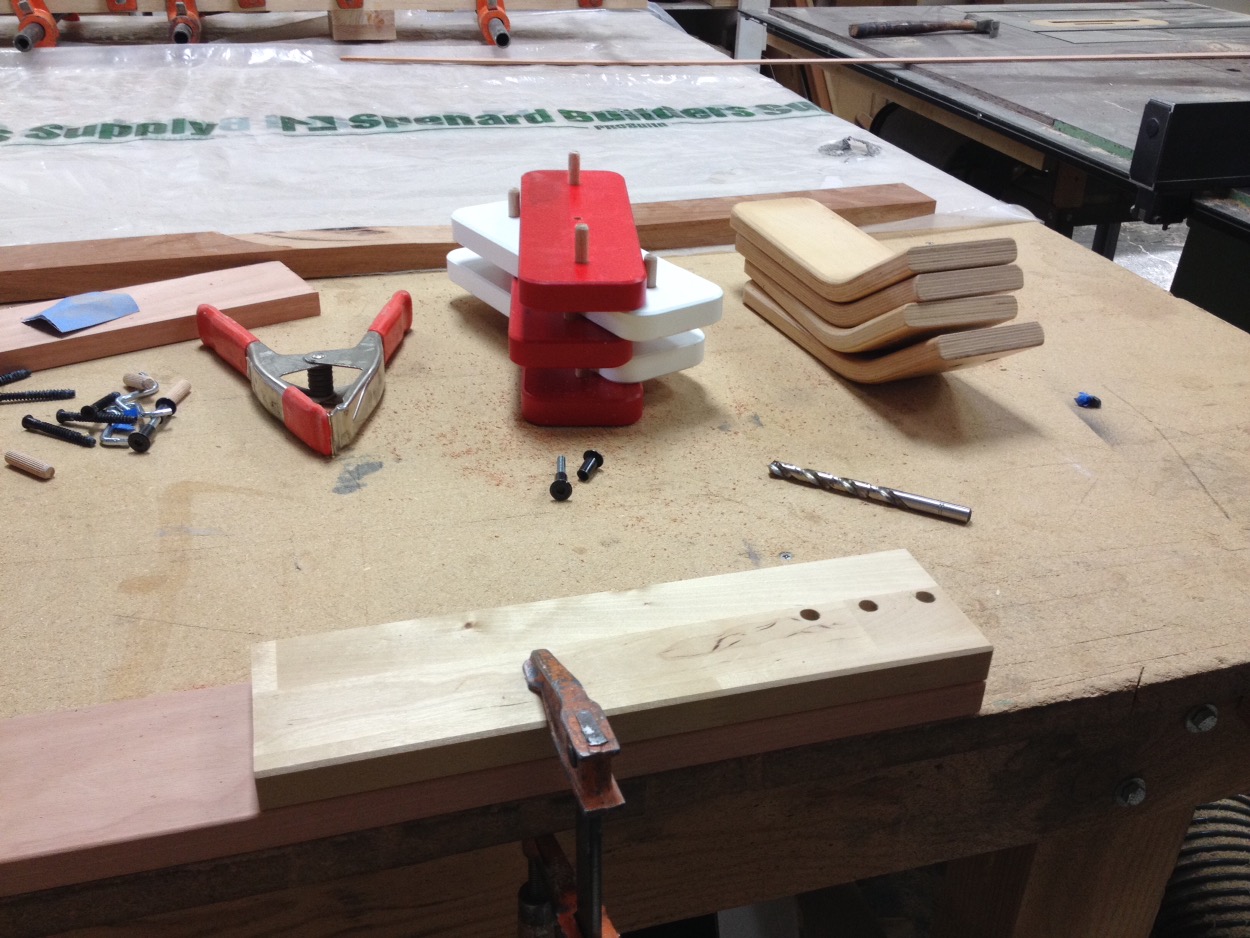

I marked where the holes were to be drilled. Then UW taught me how to use a great big drill press. I needed two hole sizes. I drilled ten holes deep into the board vertically. We drilled five vertical holes of a smaller size by hand.

The beam is composed of five lozenges. Each lozenge has three penetrations. Two receive short dowels, the center penetration goes all the way through and is secured by a screw. So 15 holes across the top.

The four support legs are likewise secured by two dowels each and a long bolt all the way through. Very strong.

Many holes later, plus rounding the edge with finish router, I’d made a thing. I enjoyed spending several hours with Uncle Walter, asking he and Mark questions. They are both dreadfully competent and that is a very fine thing indeed. It was kind of them to help.

The support beam is drying in the garage. I had a bit of clear varathane from a different project. Slapped on a coat just before E and papa returned from their adventures.